Factory & Quality Control

Our modern manufacturing facility is equipped with advanced production lines and comprehensive testing equipment, ensuring every product meets international quality standards.

Production Capabilities

Our facility combines modern manufacturing equipment with stringent quality control processes to deliver reliable, high-performance wire and cable products.

6 Extrusion Lines

Six fully operational extrusion production lines providing large-scale manufacturing capacity for diverse wire and cable products.

Complete Testing Lab

Full suite of detection and testing equipment including aging test ovens, tensile testing machines, and electrical property analyzers.

Advanced Processing

Electron beam irradiation cross-linking, fiberglass braiding, multi-layer insulation, and precision crimping capabilities.

OEM/ODM Services

One-stop custom processing including cutting, stripping, crimping, terminal crimping, and complete cable assembly.

Quality Inspection

Every production batch undergoes rigorous quality inspection covering electrical properties, insulation resistance, and mechanical strength.

Standards Compliance

Products manufactured to CCC, UL, and ISO9001 standards with full traceability and documentation for every order.

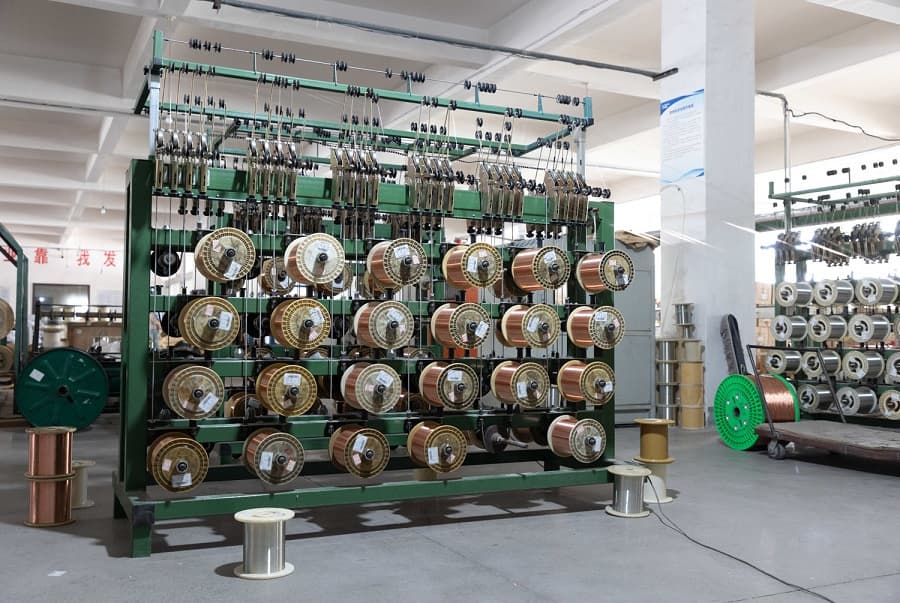

Inside Our Factory

Take a look at our manufacturing facility, production lines, testing laboratories, and product warehouse.

Rigorous Quality Control Process

Our comprehensive quality management system, certified to ISO9001 standards, ensures every product undergoes stringent testing before reaching our customers. We maintain complete testing and inspection equipment to guarantee product reliability and safety.

- Incoming raw material inspection and testing

- In-process quality monitoring at each production stage

- Electrical property testing (insulation resistance, dielectric strength)

- Mechanical testing (tensile strength, elongation, abrasion)

- Temperature resistance and aging tests

- Dimensional accuracy and visual inspection

- Final product certification and documentation

- Packaging inspection before shipment